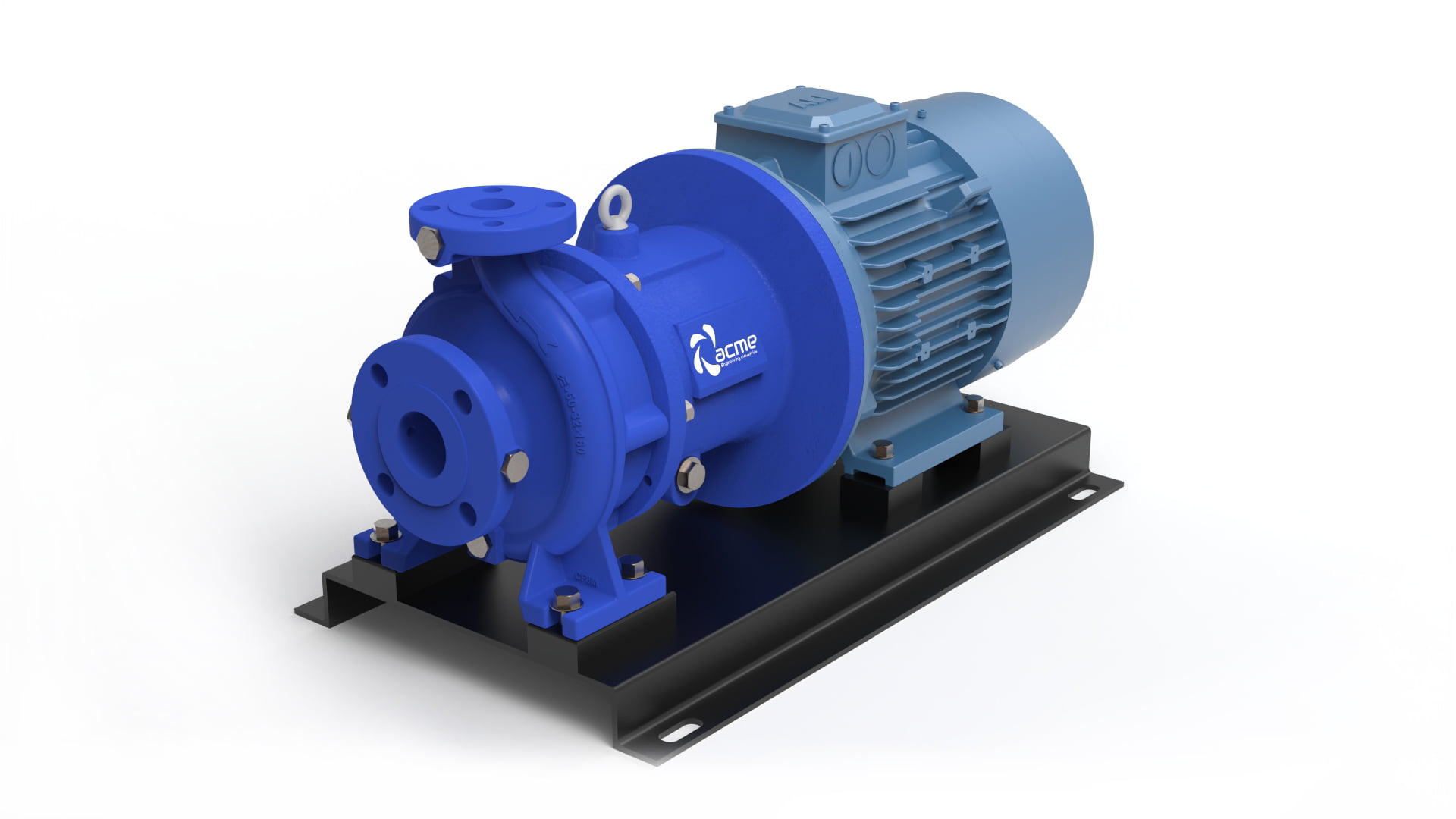

Magnetic Drive Process Pump

Features :

- Single stage Horizontal Centrifugal pump

- Pumps designed according to DIN EN ISO 2858

- Specially developed Magnets for longer life

- Double bearing cartridge design for better performance

- Hydraulically balanced impeller for minimum bearing loads

- Simple modular construction for ease of maintenance

- Back pullout design to facilitate inspection and maintenance

- High level of durability and reliability

- Optional dry run relay available

- Options for leak detection are available that eliminate any

leakage to environment

Benefits :

- As harmful or risky liquids, exotic liquids, acids, alkalis, corrosives, contaminants and toxics are pumped, magnetic drive pumps are commonly utilized.

- Ideal for ultra-pure liquids and liquids that are difficult to seal.

- To prevent hazardous liquids from leaking to the surroundings, sealed pumps used in these types of services can leak over time or require complicated, costly double seals, which can result in safety hazards, downtime, and increased maintenance requirements.

- Very much suitable to liquids which crystallize on mechanical seal faces and causes seal failure. To avoid this flush

system is used which increases cost of maintenance, energy consumption and seal flushing liquids. - As there is no Mechanical seal, it improves pump performance, reliability and availability of pump.

- Removing the seals also prevents the friction loss, wear, costs and noise.

- The magnetic coupling will soften any shock or spike torques. Even in extreme situations, it will act as a fuse.

- Since the pump chamber is totally isolated from the electric motor by a wide air gap, there is virtually no heat transfer from the electric motor.